Oyster Flood Gate Installation Instructions

Surface Mount Installation Instructions

Preparing for Installation

The first step to prepare for installation is to mark two straight lines across your opening, spaced according to the diagram provided. These lines will serve as markers for the location of the two strips of neoprene sealing material that will be used to seal the units to the surface below.

Laying the Adhesive Line

Generously apply construction grade silicone adhesive along the marked lines, on to which the neoprene sealing strips will be placed.

Laying the Neoprene Strips

Place the strips on the silicone adhesive in two parallel lines, spaced to align with the support frame of the flood panel.

Ensure Neoprene Strips Are Aligned

Check neoprene strips to make sure they are aligned and spaced properly for panel installation.

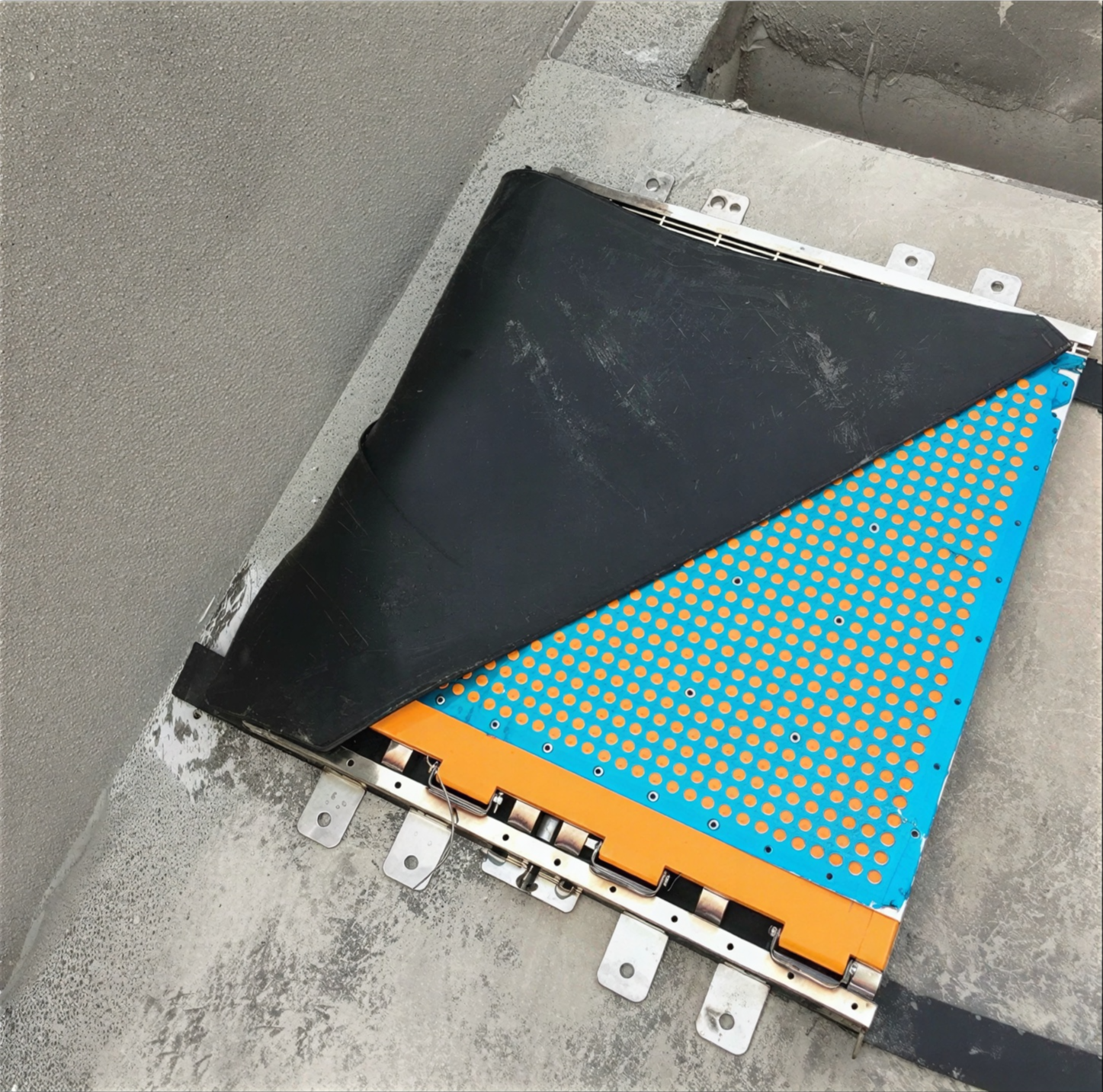

Rivet Triangular End Seals to Panels

Position the black triangular end seal between the anti-skid surface layer and the load bearing layer of what will be the last panel towards the wall on either side. Position the seal so that the short side of the triangle faces inward, away from the water side and the flat side faces towards the water side. Drill pilot holes and place rivets into position. Secure rivets, connecting the seal to the end panel.

Place Caulking on The Underside of Panels

Apply caulking to the underside of the flood panels, on both the support that runs parallel to the waterside and on the adjacent support that runs on the inside of the barrier.

Position First Panel For Install

Place and position the first panel, leaving 2.5-3.5” of space between the panel and the wall. This allows enough room for the triangular end seal to bend and rise as the automatic flood panel is deployed.

Add Additional Panels in Sequence

Continue positioning panels in sequence, inserting foam sealing strips at the connection between the modules.

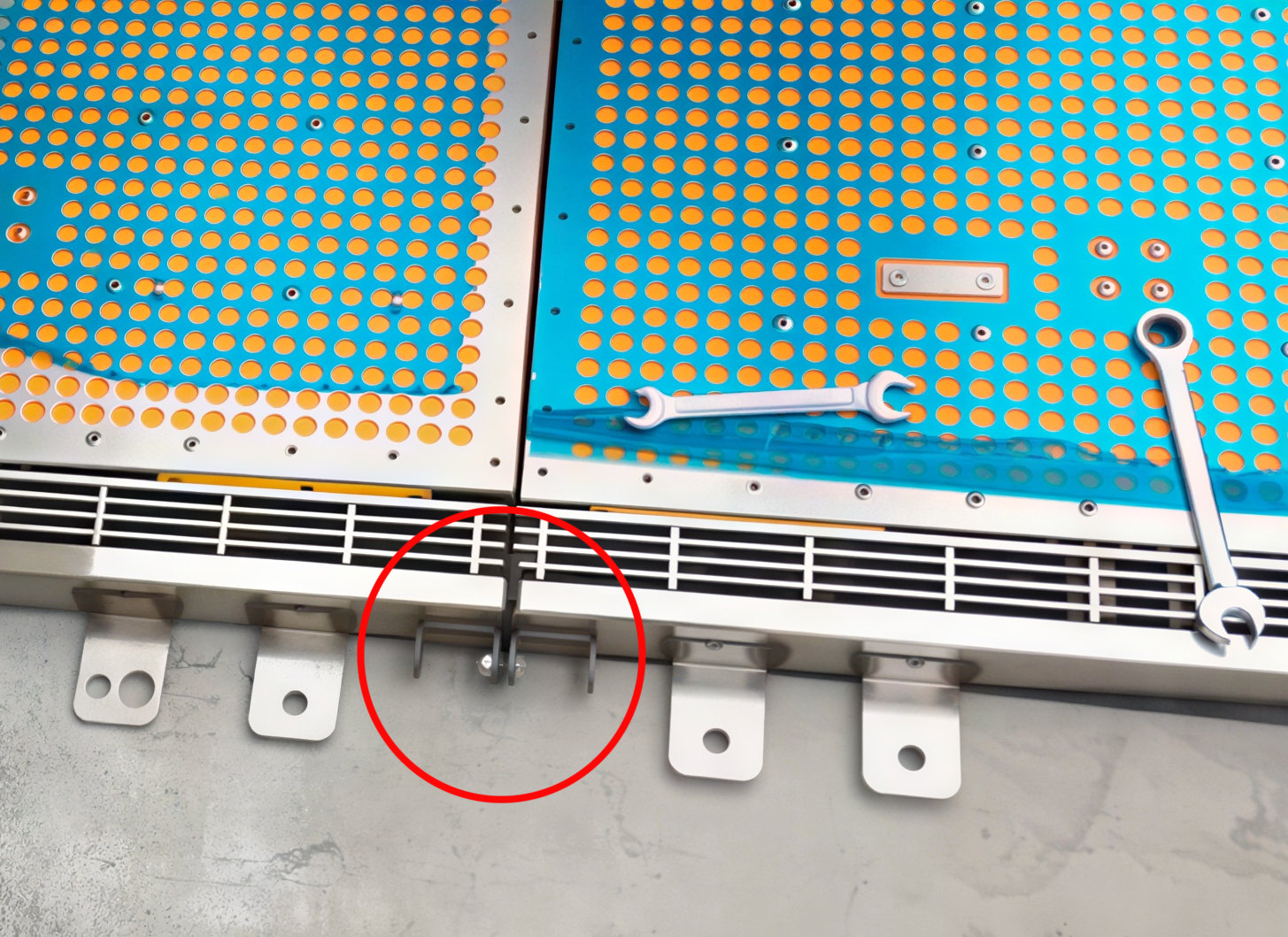

Connect Panels To Eachother

Lock panels together using the connection modules, with M8 self locking bolts and nuts. Once all panels are connected. Confirm positioning of panels in preparation for anchoring.

Drill and Anchor Ends of First Panel

Drill and place M10 expansion bolts to anchor the first panel into position. Remember to leave 2.5”-3.00” of space between the panel and the wall on either side.

Continue Anchoring Panels

Continue drilling holes through anchoring tab and insert and tighten M10 expansion bolts to fasten panels to the ground. We recommend staggering drill holes and anchoring, anchoring 1-2 locations per panel and then returning to drill and anchor through the remaining anchoring tabs.

Add filler pieces to ends at wall

Cut Z shaped extrusion to span the remaining opening. Use adhesive caulk to seal the connection between the extrusion and the end panel and the extrusion and the wall. Z extrusions are used on both sides of the opening AND on both sides of each panel (waterside and dry side). Bolt the Z shaped extrusion into position using M6 * 65 small expansion bolts. Be sure to cut the Z extrusion to overlap the panel edge by about 2”

Position and Anchor Ramped Edge Pieces

Position ramped edge pieces on both sides of the flood gates panel, drill anchor holes using the holes in the ramps to guide you. Bolt into place using expanding anchor bolts.

Note: Steel end ramps are depicted as Yellow in these instructions but all end ramps are now painted Black.

Slide the Silicone and Steel Sealing Strips Between Modules

Slide the silicone sealing strip, together with the steel sealing sheet, between the anti-skid aluminum top plate and the next layer.

Ensure The Sealing Strip Is Properly Positioned

Take care to ensure that you place the two layers into position, such that they evenly span the seam between panels

Drill Holes in Preparation for Rivets

Drill holes for 4.8mm rivets on both sides of the seam between the panels.

Insert and Fasten Rivets

Insert and fasten rivets, locking the seaming sheet layers into position and creating a watertight seal.

Lay Rubber Sealing Strip Along Hinged Area

Lay the rubber sealing strip along the hinged area to seal the connection between the flip up flood gate panel and the frame.

Lay Steel Fastening Strips Over Rubber Seal

Align and lay the flat steel fasting strips on either side of the rubber seal, positioning them over the flip up panel edge on one side and the lower frame on the other side. The metal strips fasten the rubber seal to either side of the hinged opening, creating a solid and continuous water seal.

Drill Holes and Rivet Steel Strips to Panel and Frame

Use existing pre-drilled holes in metal fastening strips to guide drilling for rivets. Then insert and fasten rivets

Place and Rivet Rubber End Triangle

Place the bottom corner of the rubber triangle seal (for the connection to the wall) under the end of the metal fastening strip and drill and rivet into place, connecting this seal to the hinge seal.

Cut and Add Metal Strip

Measure and cut to size an additional section of the metal fastening strip and position it over the edge of the triangular sealing strip. Drive and rivet the extra piece to connect the edge of the triangular sealing rubber to the Z metal extrusion filler piece used to bridge the distance between the panel and the wall. Generously apply caulk at the corner intersection between the Z extrusion, the rubber and the wall, to create a good seal.

Cut and Add Metal Strip

Measure and cut to size an additional section of the metal fastening strip and position it over the edge of the triangular sealing strip. Drive and rivet the extra piece to connect the edge of the triangular sealing rubber to the Z metal extrusion filler piece used to bridge the distance between the panel and the wall. Generously apply caulk at the corner intersection between the Z extrusion, the rubber and the wall, to create a good seal.

Cut and Add Metal Strip

Place rubber triangular seals (both sides of barrier run) against the wall and align metal fastening strip section over the top edge of the rubber seal. Drill holes for M6x65 expansion bolt anchors, place anchors, and tighten down the metal fastening strip and rubber seal, forming a watertight connection..

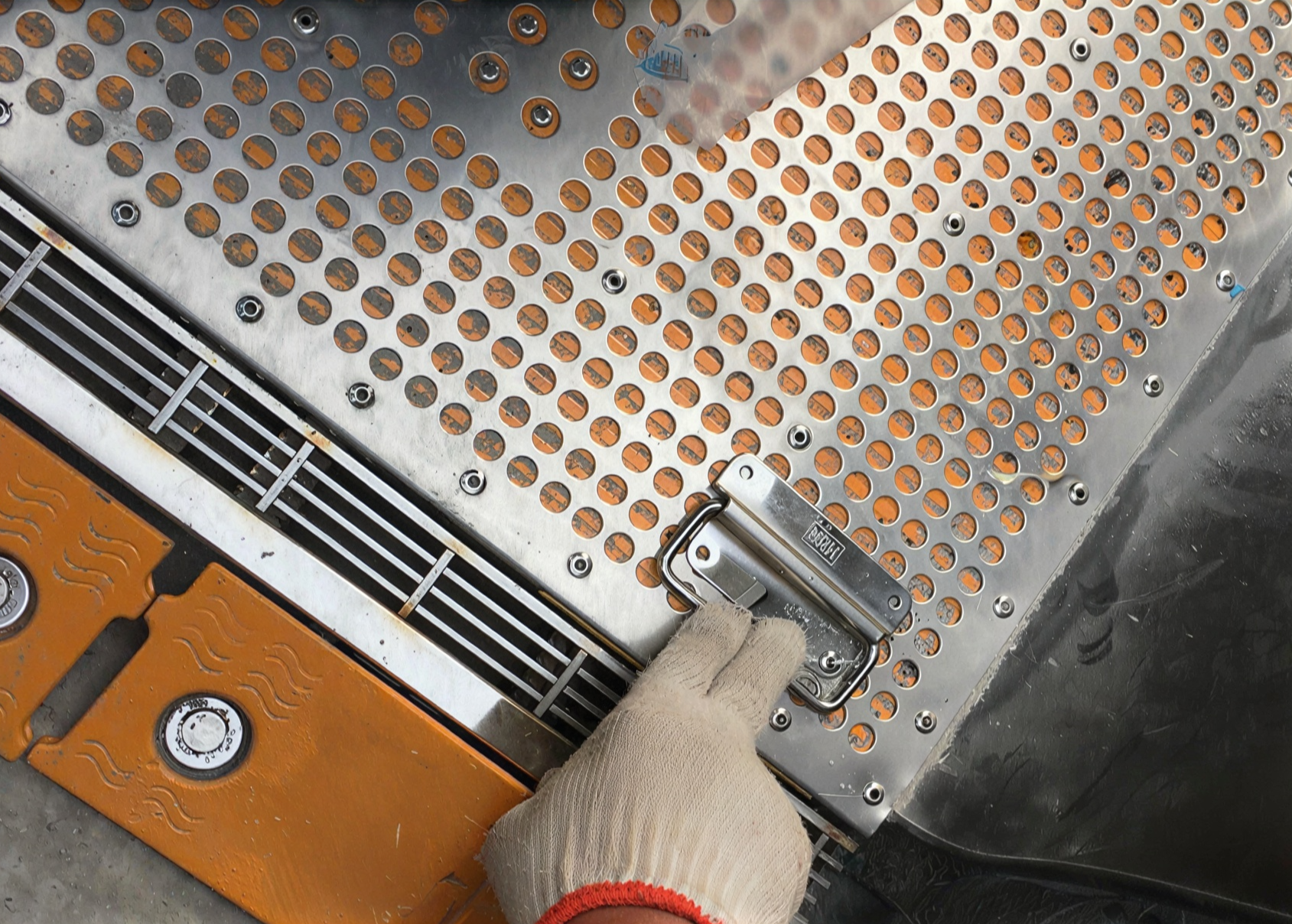

Add Auxiliary Lifting Handle

The auxiliary handle is used for opening the flood gate for maintenance and cleaning. For flood gate system with a total length of 15 ft or less an auxiliary handle should be installed on the left and right barrier panels respectively. For those with a total length of 15-30 feet, a 3rd auxiliary handle position should be added in the middle position, and for longer sections, additional handles should be installed roughly every 15 feet.

To install a handles, drill and rivet handles into position via the 4 pre-drilled holes.

Add Auxiliary Lifting Handle

The auxiliary handle is used for opening the flood gate for maintenance and cleaning. For flood gate system with a total length of 15 ft or less an auxiliary handle should be installed on the left and right barrier panels respectively. For those with a total length of 15-30 feet, a 3rd auxiliary handle position should be added in the middle position, and for longer sections, additional handles should be installed roughly every 15 feet.

To install a handles, drill and rivet handles into position via the 4 pre-drilled holes.

Your Oyster Flood Gate Installation is Complete

Congratulations on installing your Oyster Automatic Flood Gate System, one of the most innovative self-rising flood barrier systems on the market.