Automatic Flood Barriers

Oyster™ Self-Rising Mechanical Flood Gate

Automatic ramp flood protection for garages, driveways, loading docks, transit entrances and more.

The Garrison Oyster™ Self-Rising Mechanical Flood Gate is a hydrodynamic, water-activated flood barrier designed to protect any downward-sloping entrance — including parking garage ramps, driveway ramps, transit and subway station openings, loading docks, tunnels, and other below-grade access points.

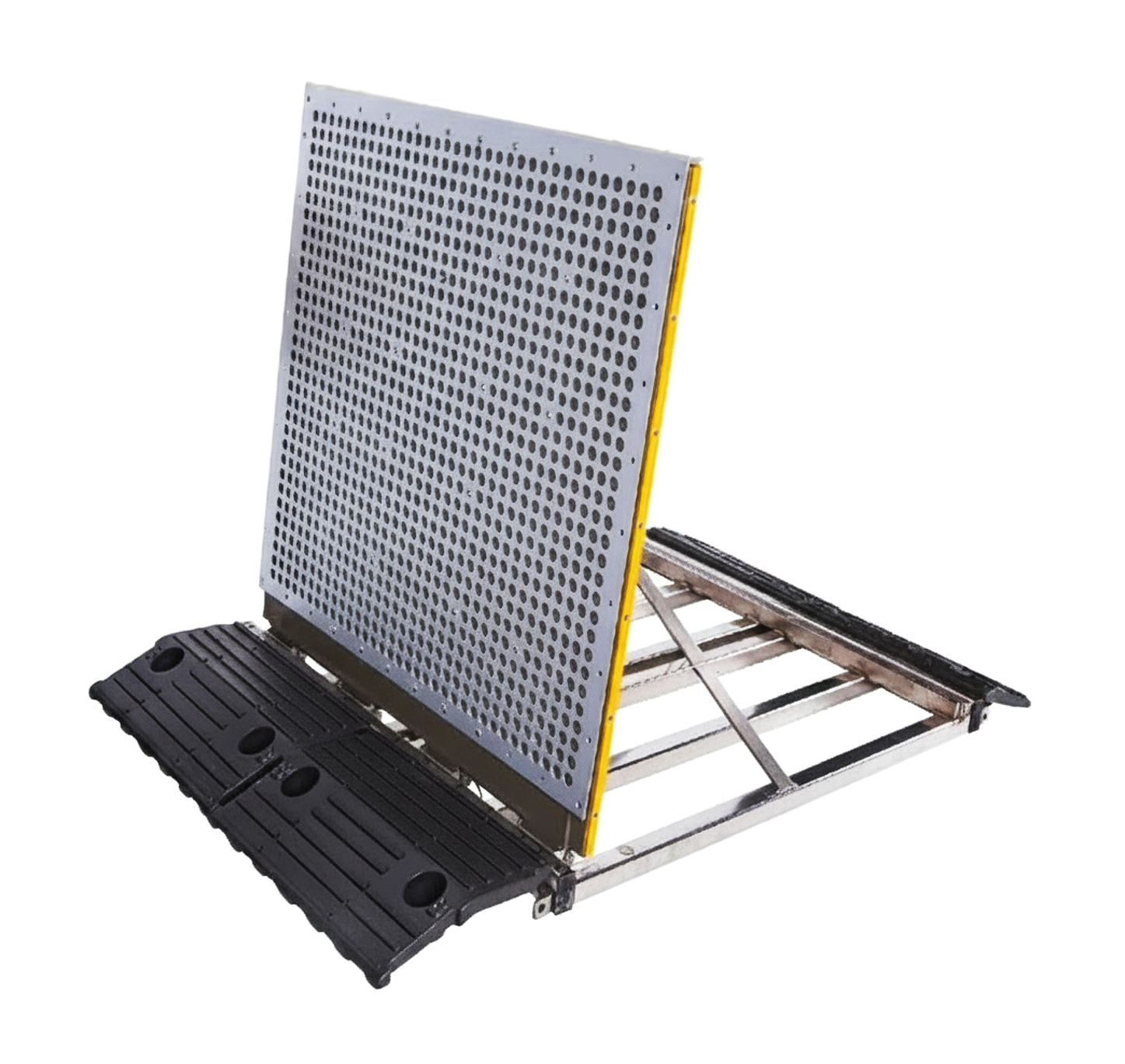

In normal conditions, Oyster lies flat on the ramp so vehicles and pedestrians can pass freely. When floodwater approaches, it flows into the barrier’s internal cavities and uses its own buoyancy to automatically lift the panel into a vertical flood wall — without power, motors, or human intervention. This passive flood gate system resets to the closed position when floodwaters subside.

Up to 48” of Protection Height

Self-Deploys without power

Full Ramp and Opening Protection

Where Can I Use The Passive Oyster™ Flood Barrier?

Designed for high-risk ramps & openings

Parking garage entrances and exits

Driveway ramps to underground parking or back-of-house service areas

Transit systems and subway station openings

Loading dock ramps and service tunnels

Stadiums, arenas, malls, convention centers, hospitals, universities and data centers

Any site where water runs down a ramp toward critical below-grade areas

How the Oyster™ Automatic Flood Gate Works

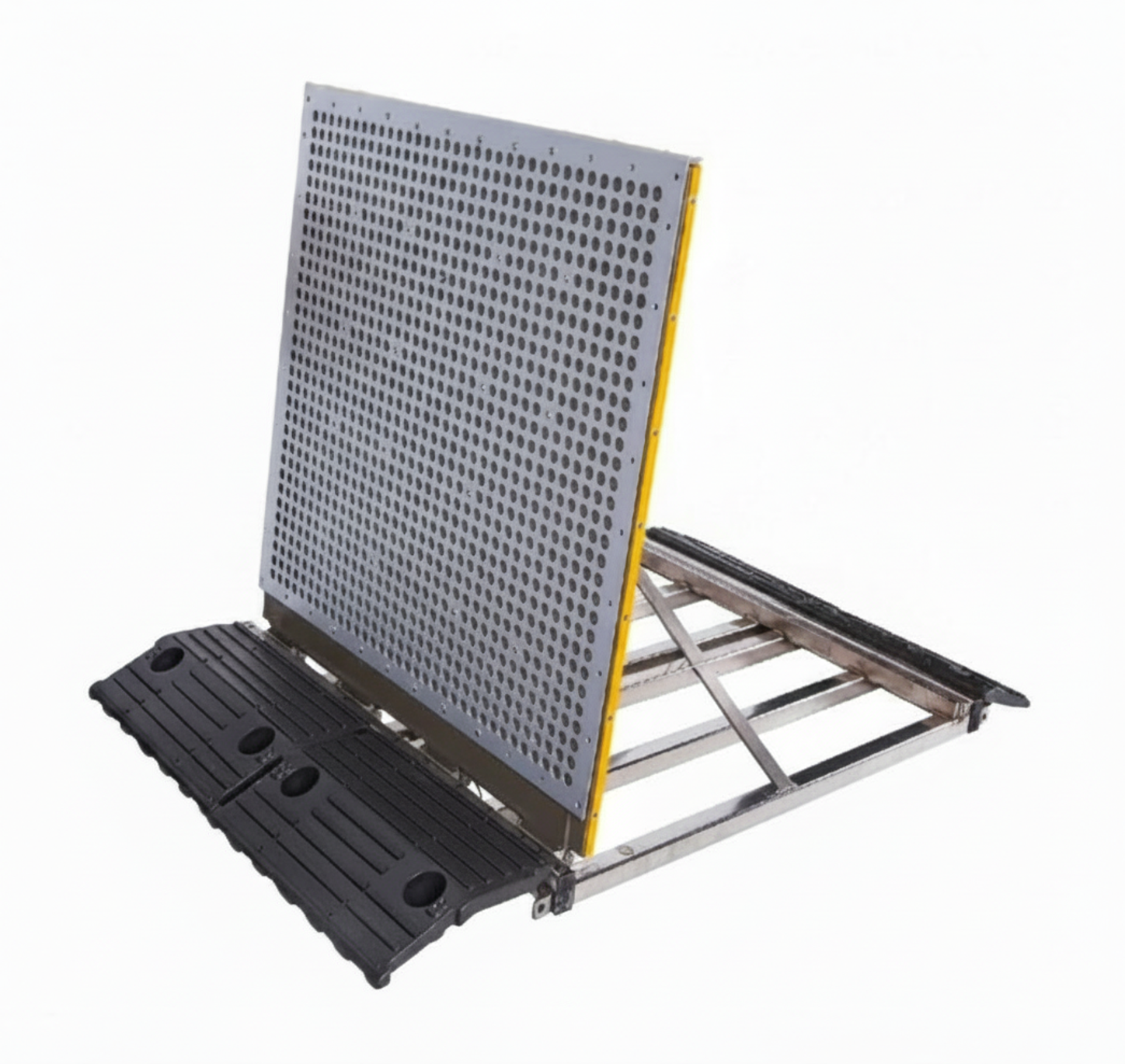

Oyster™ Barrier Closed Position

Oyster™ Flood Gate Open Position - Dry Side

Oyster™ Automatic Flood Gate Open Position - Water Side

The Oyster flood gate uses a passive hydrodynamic mechanism in each module to sense rising water and lift the panel, creating a flood wall against incoming water.

Standby (Dry Conditions)

Vehicles and pedestrians pass normally over the anti-skid driving surface. Flood panels sit flush with concrete or lay just on top of the surface.

Rising Water & Activation

Floodwater approaching the flood barrier flows through inlets into internal water-storage cavities inside each module.

Buoyancy acts on internal floatation plates, which in turn push the rotating flood panel upward.

Automatic Deployment

As water depth reaches the design threshold, flood barrier modules rise into the raised position and lock into a near-vertical position.

Continuous ramp seals and side-wall flexible seals create a tight seal, blocking water from entering the protected opening.

Oyster is a fully passive flood protection system, requiring no human intervention.

Controlled Drainage and False Deployment Prevention

Integrated drainage and water outlet controls allow small amounts of water to drain away, preventing nuisance deployment from shallow ponding. Only when inlet flow exceeds drainage capacity does the barrier rise.

After the Flood

Once the event ends, water drains from the cavities.

Operators follow a simple procedure to lower the panel back to its flat position and visually confirm seals and hardware for future use.

Why Use Oyster™ Self-Deploying Flood Barriers?

Fully automatic operation (no power required)

Hydrodynamic system rises using the ballast of floodwater; no power, pumps, motors, or staff deployment required. Oyster is a fully passive flood barrier.

Drive-through safe

Four-layer, heavy-duty panel structure supports vehicle loads; cars and light trucks can pass over the closed barrier and, if necessary, safely drive out over the ramp even when the barrier is raised (within design limits).

Flat, low-profile when not deployed

Panels are installed in-ground or laid on top of concrete with a ramped thickness of only 2.0”–3.9”.

Modular and adaptable

Standard 23.6” wide flood gate modules. Non-standard “filler” units come in 6.3”, 11.4”, 13.2” and 18.5” wide sections, allowing the system to match almost any ramp or opening width with a clean fit.

Flexible side sealing system

Adjustable side seals and optional Z-profile gap fillers handle variations in wall alignment and allow installation where the distance from barrier to wall ranges roughly 2.0”–5.9” depending on height.

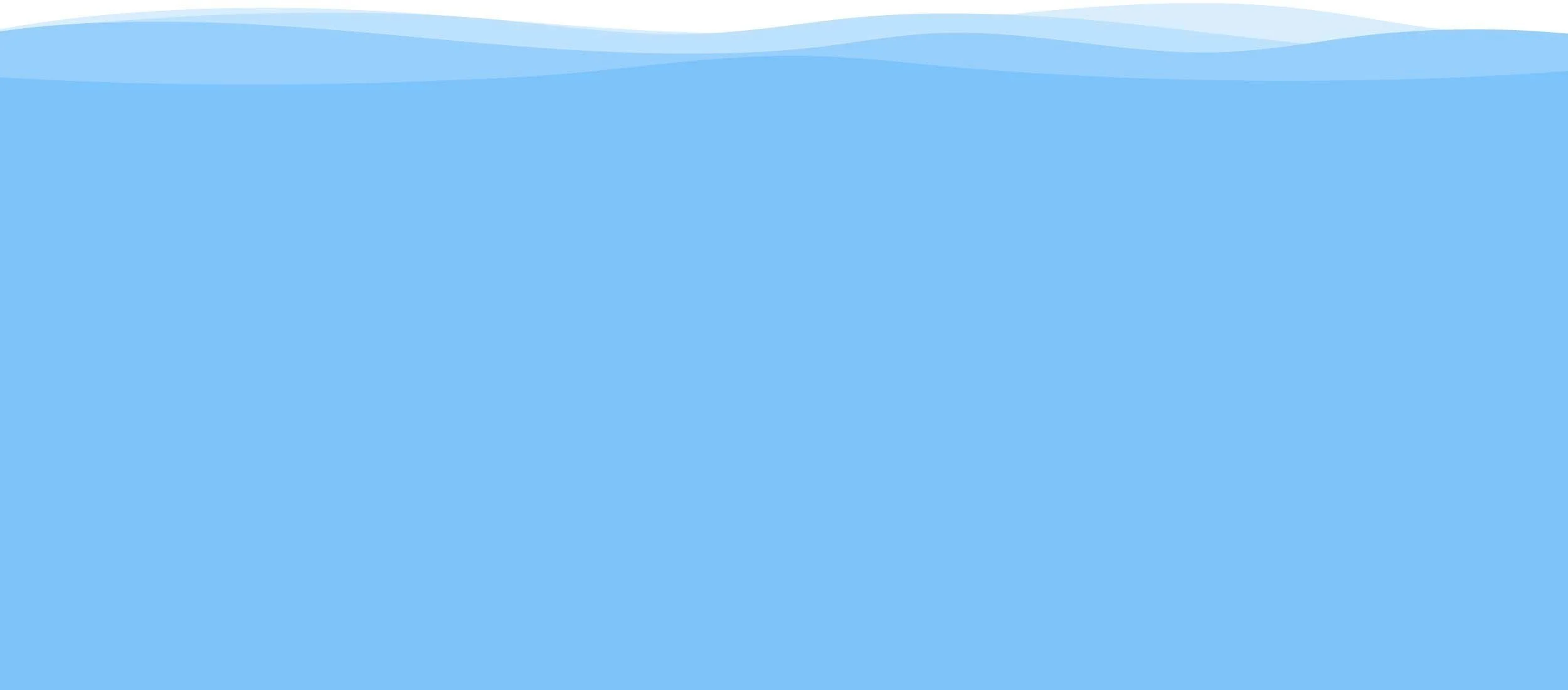

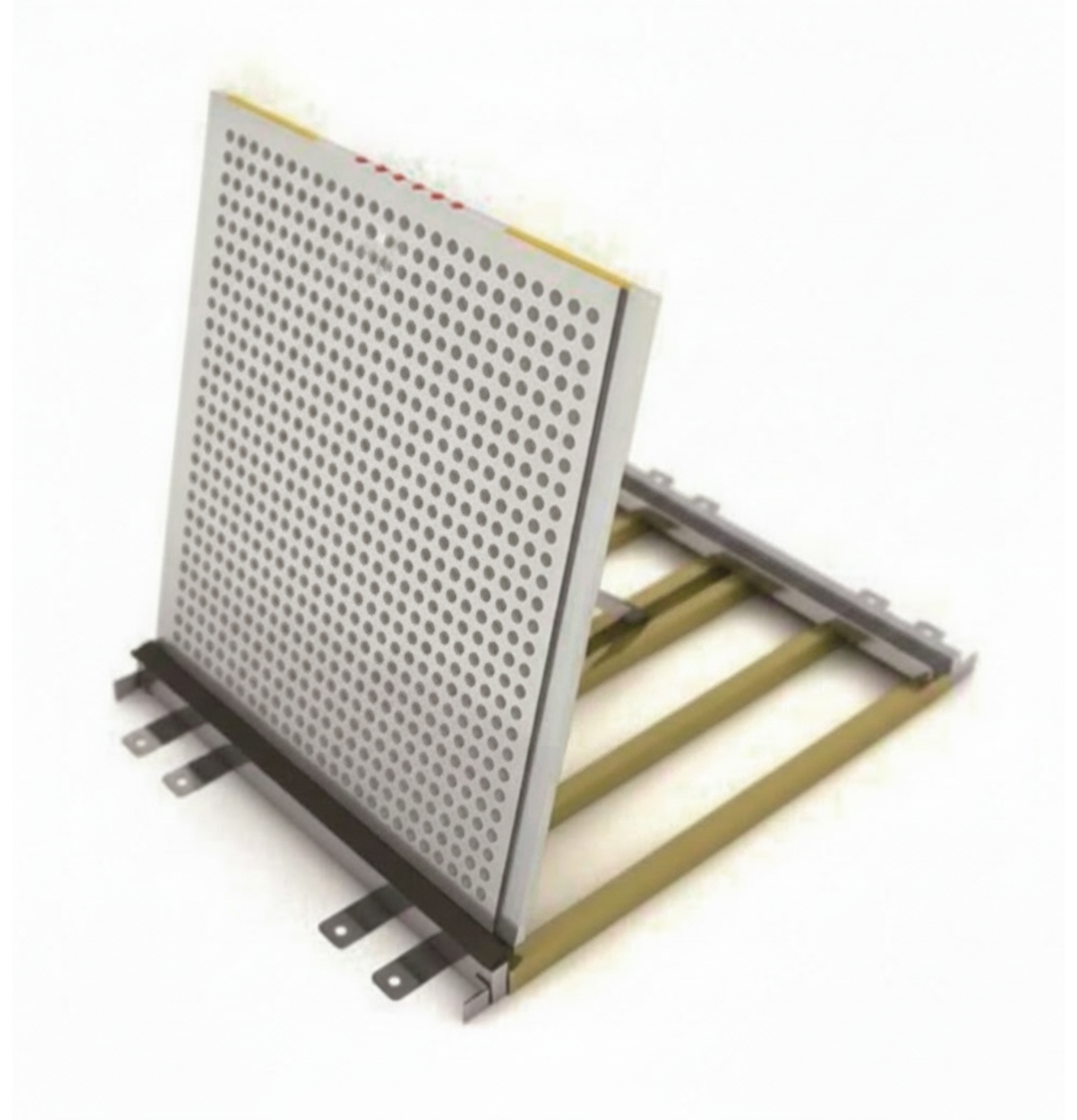

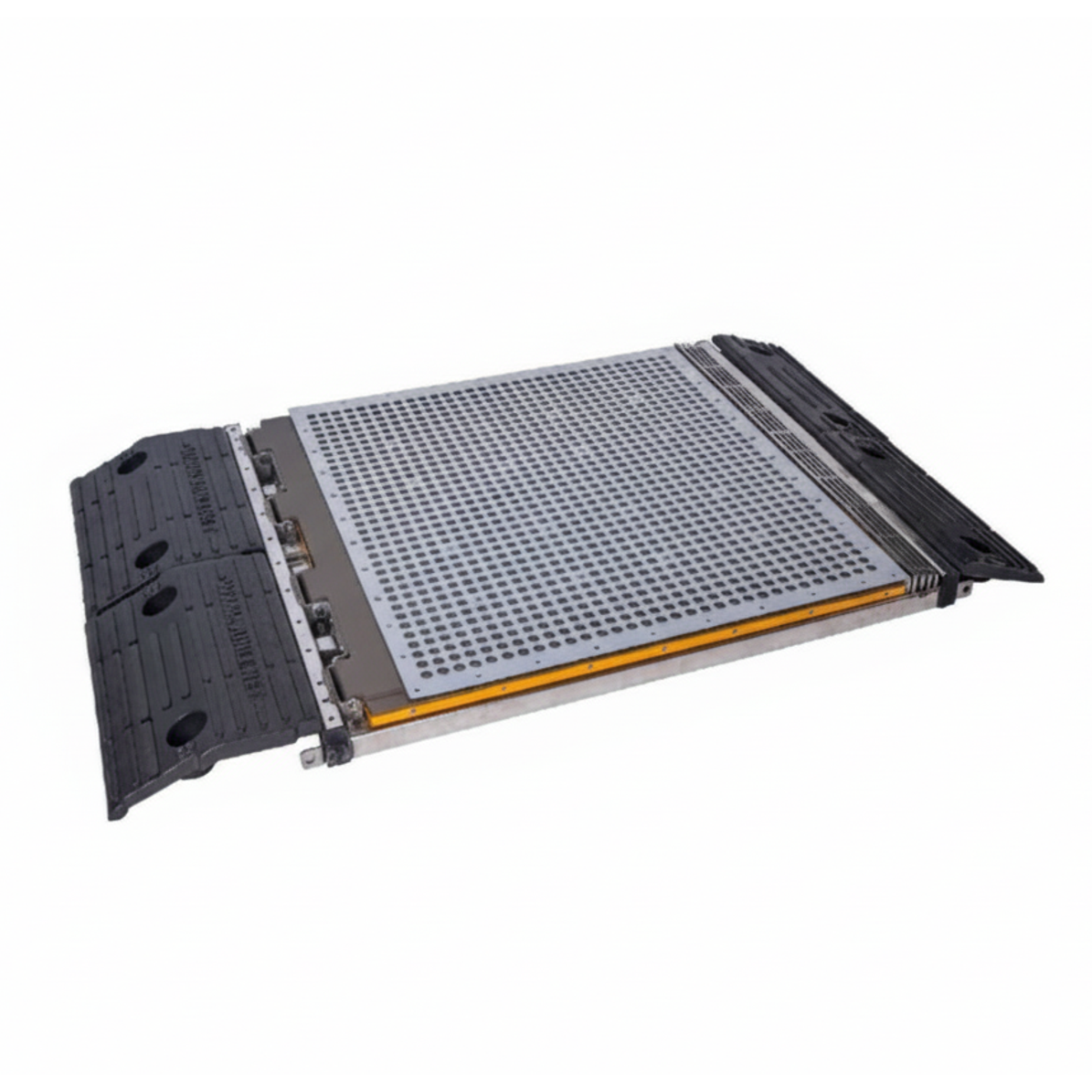

In-ground or surface-mounted versions

Choose a recessed embedded frame for new construction or a surface-mounted frame for retrofit projects when the slab cannot be cut. Both are based on the same core barrier modules.

Low maintenance, long life

Constructed from aluminum, aluminum castings, 316L stainless steel and nodular cast iron, with EPDM/silicone rubber sealing elements

Proven performance

Proven performance at hundreds of installations globally, this passing flood gate system continues to perform time and time again.

Durable

Built using durable materials, hardware and construction for long life.

3 Heights

Available in 24”, 36” and 48” heights, depending on your protection needs.

Automatically Rises

Passive glood gate rises automatically using hydrostatic pressure. No electricity or battery power needed.

Automatic Flood Gate System Components

The Oyster™ Self -rising flood gate system is built from standard modules plus non-standard filler modules, with flexible side seals at each wall. There are two types of installation types:

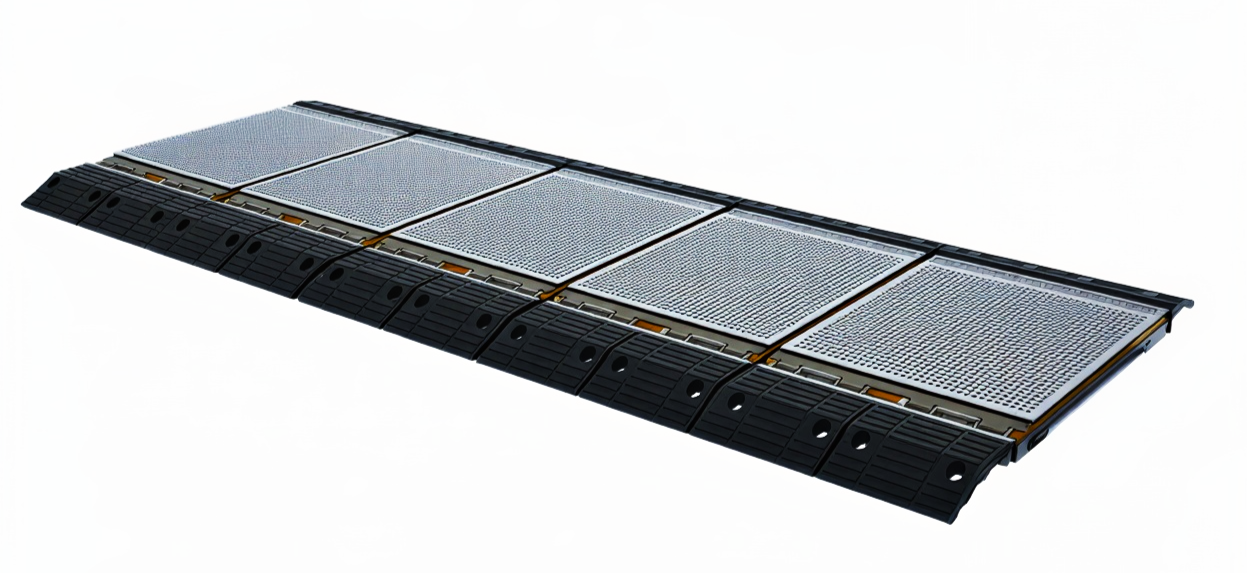

Surface-mounted (panels fasten to the top of existing concrete or asphalt)

Embedded/in-ground (recessed concrete installation) method.

Deployment operating principle: Passive hydrodynamic buoyancy; no external power required. Panels flip up automatically without any electricity or intervention.

Control & alarms (optional): Local battery powered alarm box / control panel to signal deployment status and issue audible/visual alerts.

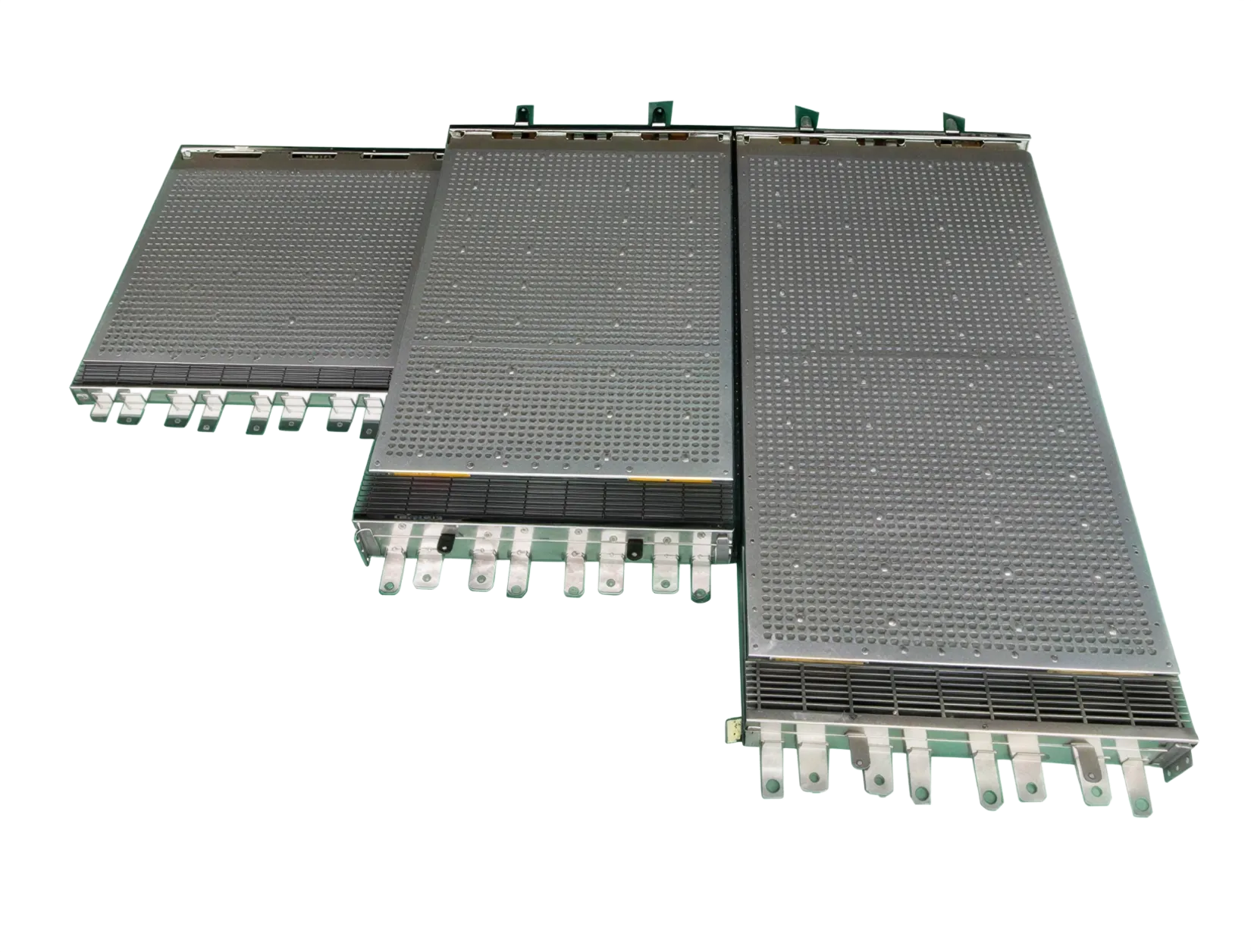

Standard Flood Gate Modules

Standard width: Approx 23.6” per module

Effective width with splice: 23.75” (allowing for some spacing for joint hardware)

Available water-retaining heights: 24", 36", 48"

Panel Thickness: 2” for 24” panels, 4” for 36” and 48” panels

Non-Standard “Filler” Modules

To achieve a closer fit, Oyster™ uses narrower “filler” modules. These can be combined to make up opening size differences and to get closer to side walls.

Available filler widths: 6.3”, 11.4”, 13.2”, and 18.5”

Example: For a 9ft opening, you would use 4 ea. x 23.75” standard units plus 1 ea. × 6.3” filler would create a 101.3” section (8ft 5.3”). The final 4.7” distance is spanned using flexible rubber side-wall seals on either side of the opening.

Flexible Side-Wall Seals

To span the final distance between the panels and side walls and to create a secure seal on either side, flexible rubber sealing plates span from the panel run to the wall and flex upwards as the flood barrier rises.

Typical design ranges (distance from wall to main frame):

24” height: preferred wall distance 2.4”–3.9” (tolerance 2.0”–4.3”)

36” height: preferred wall distance 3.1”–4.7” (tolerance 3.1”–5.5”)

48” height: preferred wall distance 3.9”–5.5” (tolerance 3.5”–5.9”)

Triangular Side seals are fixed to the wall with stainless steel strips and anchors and are sized specifically for each height of protection.

Ramped Edge Pieces

When utilizing the surface mount method, choose from standard powder coated steel ramps or wider, more pedestrian friendly ramps. Wider ramps are suitable for non-vehicular access at sites like transit systems, malls or lobby entrances. In ground Oyster systems have powder coated steel filler sections in place of ramp

Automatic Flood Gate System

3 Heights Depending on Expected Flood Depth

Flexible Triangular Side Seals Prevent Leakage Where the Oyster Flood Barrier Meets the Wall

Construction & Materials

Each standard Oyster flood gate panel is a four-layer composite engineered for strength, buoyancy, and skid resistance:

Panel Construction:

Anti-Skid Surface Layer

Aluminum tread top layer with anti-slip texture for vehicle and pedestrian safety.

Load-Bearing Layer

Heavy-duty cast-aluminum structure, designed to handle vehicular traffic; rated for garage and ramp applications.

Buoyancy Layer

316L stainless steel structure with electrophoretic coating and spray finish, creating sealed cavities for buoyant elements that lift the panel.

Protective Underside Layer

304 stainless steel protecting the buoyancy system from impact and corrosion.

Base Frame

Base frame and structural plates: aluminum and aluminum casting

Other Key Elements:

Side sloped sections: nodular cast iron or 304 stainless steel, depending on style (Standard or Pedestrian).

Sealing components: EPDM or silicone rubber (ground seals, inter-panel seals, side seals, wall seals)

Frequently Asked Questions

-

-

The Oyster is a hydrodynamic, self-rising mechanical flood gate designed to protect downward-sloping entrances such as parking garage ramps, driveway ramps, loading docks, tunnels, and transit station openings. In normal conditions it lies flat on the ramp; when floodwater approaches, it automatically rises to form a rigid flood wall without the need for power, motors, or manual deployment.

-

As water flows toward the ramp, it enters internal cavities in each Oyster module. Increasing water level creates buoyancy that lifts the rotating panel up and into a locked position. Flexible side and ground seals engage as it rises, creating a continuous flood wall across the width of the opening.

-

Oyster flood gates is optimized for any sloped entrance where floodwater can “run down” into a below-grade space: multilevel parking garages, underground loading docks, service tunnels, back-of-house ramps, and metro or subway entrances. It is especially useful where permanent walls or doors are not practical but you need automatic protection when staff may not be on site. Oyster also works for standard openings such as loading docks. and entryways.

-

Yes. In the closed (non-flood) position the top of the panel forms a low-profile, anti-skid driving surface that vehicles and pedestrians can cross normally. When the barrier is deployed, the ramp geometry and panel design still allow emergency vehicle egress out of the protected area as the flood panels are rising.

-

No. Oyster is a passive, mechanical system. It relies on the buoyancy of floodwater acting on internal chambers to lift the panel. Optional battery powered alarm and monitoring systems can be added, but the barrier will still deploy even if power is lost.

-

Standard water-retaining heights are 23.6 in, 35.4 in, and 47.2 in (600, 900, and 1200 mm).

-

Oyster can span nearly any sized opening as modular flood barrier sections connect to extend the length of protection. Each standard module is 23.6” (600 mm) wide (about 23.7” / 603 mm including the splice). To fine-tune the total width, we use non-standard “filler” modules in widths of 6.3”, 11.4”, 13.2”, and 18.5” (160, 290, 335, and 470 mm). By combining standard and filler modules, Oyster can match the clear width of most ramp openings with a very tight fit. The final spacing is spanned with a flexible rubber seal that connects the panels to the adjacent opening wall.

-

Sealing is achieved through several elements working together:

Ground seals: rubber sealing strips bonded into grooves in the base frame with structural adhesive form a continuous seal with the ramp surface.

Inter-panel seals: flexible seals between adjacent modules prevent leakage at joints.

Side-wall seals: flexible rubber side plates, clamped to the wall with stainless steel strips and expansion anchors, bridge the gap between the end module and the ramp walls and are sized for each water gate height.

The system is designed to tolerate real-world construction variances in both the slab and the walls.

-

The side-wall sealing system allows the main frame to be installed slightly inboard of the walls:

23.6 in (600 mm) height: preferred distance approx. 2.4–3.9 in (60–100 mm)

35.4 in (900 mm) height: preferred distance approx. 3.1–4.7 in (80–120 mm)

47.2 in (1200 mm) height: preferred distance approx. 3.9–5.5 in (100–140 mm)

Your final layout will be engineered to fit the actual ramp and wall dimensions.

-

The Oyster automatic flood gate system is an all-metal, multi-layer construction with elastomeric seals:

Aluminum and aluminum castings for the main structure

Nodular cast iron or stainless side slopes (depending on configuration)

316L stainless steel internal buoyancy and protective layers

EPDM or silicone rubber for all sealing components

-

Panel thickness in the closed position is typically about 2.0” (50 mm) for the 23.6 in (600 mm) height and about 3.9” (100 mm) for the 35.4” and 47.2” (900 and 1200 mm) heights. The top surface is finished as an anti-skid tread, and ramped transitions are designed so that there is no tripping hazard and so vehicles can cross smoothly.

-

Both. Oyster can be supplied as:

A surface-mounted system anchored directly to an existing ramp surface, ideal for retrofit projects; or

An embedded system where the frame is cast into a recess formed in a new or reconstructed ramp slab.

The core modules are the same; only the base frame and side-slope details change.

-

Oyster is engineered to hold back water to its full design height (up to 47.2 “ (1200 mm) for standard units) with appropriate safety factors for hydrostatic loading.

-

Oyster flood gates are designed for low maintenance, but periodic inspection is essential:

Keep the ramp surface and barrier inlets free of debris.

Inspect seals, side plates, and hardware at least annually (more often in harsh environments).

Perform a wet-test per your O&M manual or local code to verify smooth deployment and sealing.

Any damaged seals or components should be replaced before the next flood season.

-

The system won’t deploy with only a small amount of water, rain, or building up. The system includes drainage features that allow minor ponding or rainwater to drain away without triggering full deployment. Only when incoming water exceeds the drainage capacity and begins to build depth does buoyancy lift the panel into the flood-wall position.

-

Like other Garrison Flood Control products, Oyster systems ship from either our facility in Florida or our distribution warehouse in California. Freight logistics will be coordinated at the time of order.

-

All products currently ship from either our regional warehouse in Santa Fe Springs, California or our manufacturing and warehouse location in Pompano Beach, Florida

-

Item dInstallation time depends on ramp size, whether the system is surface-mounted or embedded, and local site conditions. As a rough guide, a typical single-ramp surface mount installation is usually completed in a day or two. For embedded systems, a contractor experienced with concrete work is recommended. Embed installs will require time to cut out or form concrete, plus additional time for curing if new concrete is poured. Then standard installation can commence. Embed installs can take 3-4 days to complete. Garrison can provide detailed guidance and, in many regions, direct installation or supervisory support.

-

Send us drawings, photos, and basic information about your ramp (width, slope, materials, target protection height, and flood history).

A Garrison flood specialist will review your project, confirm whether Oyster is a good fit, and recommend a configuration, preliminary layout, and budgetary pricing. Of course, you can also call us to discuss over the phone your needs.

-

Contact Us and speak with a flood specialist today to determine the number and type of flood gates that are right for you.

In-Ground Mount Closed

In-Ground Mount Open

Surface Mount Closed

Surface Mount Open